| |||

| RFI shielding specialist |   |

02 |   |

| for conductive adhesives and gaskets | |||

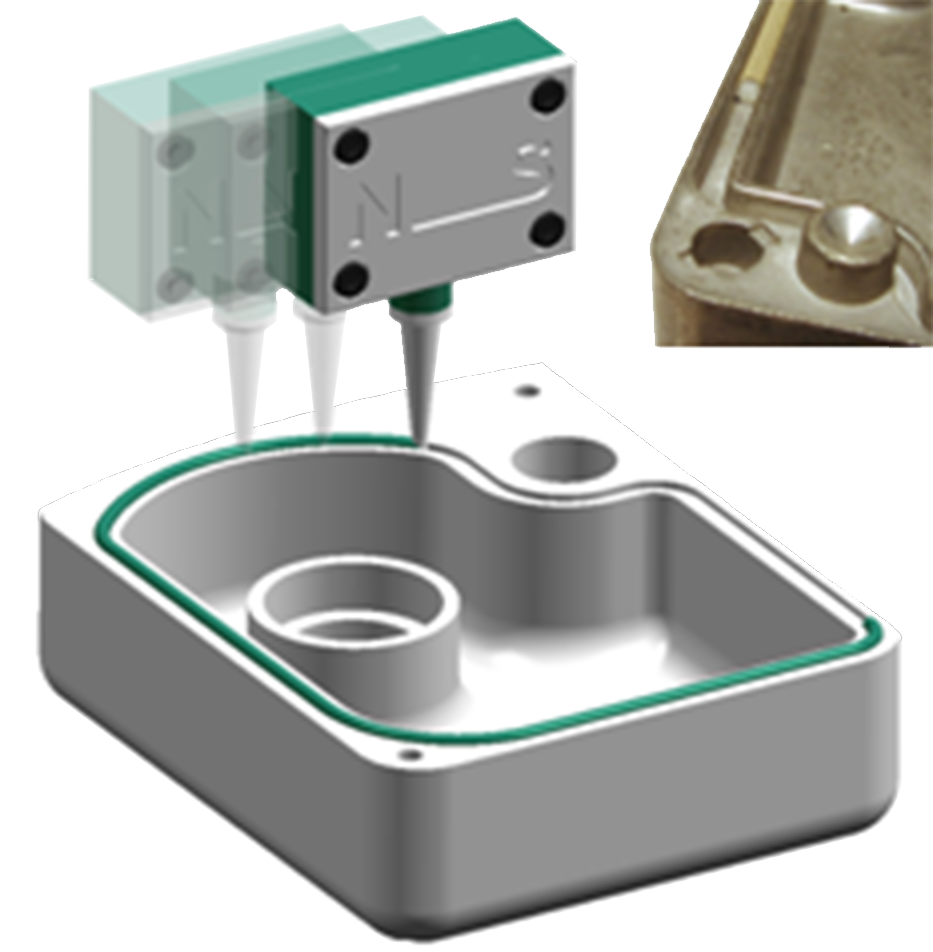

The profile RFI gasket (Form In Place) is especially interesting due to its outstanding features. The RFI gasket is dosed by a profiled and rotary dosing-nozzle onto the sealing surface of a housing in a single, process-safe operation using an X-Y-Z dosing system. There it cures at room temperature to a conductive elastic RFI gasket. By supply of the profiled and rotary dosing-nozzle it is possible to apply gaskets on housings, which have a better relation to hight and width than gaskets dosed with a conventional round nozzle. As compared to conventional gaskets lower assembly forces are needed to get the same sealing of the housings.

Cross-section of a gasket, dispensed with a

profile-nozzle

Cross-section of a gasket,

dispensed with a conventional

round-nozzle

![]()

![]()

Due to the automatic, production-safe application of the profile-molded RFI gasket, the manufacturing costs are reduced. The lower consumption of conductive materials contributes significantly to the savings.

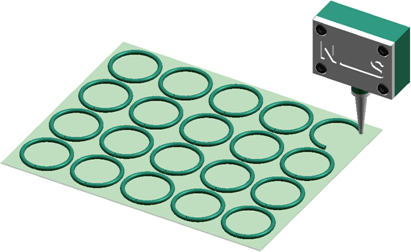

As an alternative, the gasket can be dispensed onto foil for later processing. Direct dispensing onto printed circuit boards is also possible.

Our services include the mechanical dispensing of your individual RFI gaskets directly onto on your housing parts, on foil or on printed circuit boards.

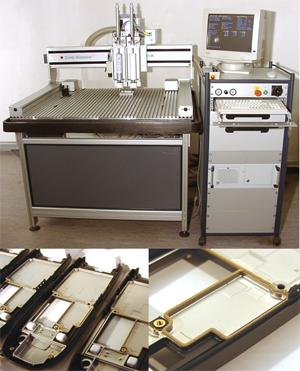

![]()

We will plan, offer and implement dosing stations as isolated or integrated components in your production line. The available machine can include your housing parts besides the freely programmable dispensers, transport facilities and depot units.

The machine can be integrated „inline“ into your production line.

| contact details: | ||

|---|---|---|

| NEUHAUS Elektronik GmbH | Tel. +49 (0)30 - 497 695 - 0 | |

| Drontheimer Str. 21 | Fax +49 (0)30 - 497 695 - 30 | |

| D - 13359 Berlin | Email: |